Hello guys,

Today, We'll discuss on Traceability.

Let's start discussion on this topic. Hopefully, you'll understand this topic.

First of all, thanks for visiting.

Below topics that are covering:

- INTRODUCTION

- WHY TRACEABILITY IS NECESSARY?

- DIFFERENCE BETWEEN TRACEABILITY & IDENTIFICATION

- HOW CAN TRACEABILITY BE IMPLEMENT IN ANY ORGANISATION?

INTRODUCTION:-

Traceability is made up of two words 'trace' and 'ability' and is used by all manufacturing industries to describe the ability to track products. Traceability is very important for manufacturing industries in which an identification number is provided to the lot of parts made in a specific unit. The identification number assigned to the lot during the traceability process is known as the lot number.

Lot / Batch Numbering:-

A lot number is a unique number assigned to a specific quantity during a manufacturing process. If a manufacturing unit gets an order to make 5000 products, then 5000 becomes a lot or batch. If an identification number is given to that lot, then that number is called as lot number or batch number. Lot number is essential in the manufacturing process as the material or product can be traced by this number.

WHY TRACEABILITY IS NECESSARY?

In IATF 16949:2016, according to clause no. 8.5.2, when an output is obtained from a production process, it produces two types of parts as output.

- Ok or Conformity (C)

- NG or Non conformity (NC)

Now there can be 3 possibilities in the NG part also.

- Rework part

- Repair part

- Scrap part

Similar outputs have been asked to identify in this clause. Traceability is very important in tracing the entire process from raw material procurement to finished goods and clarifying "when and where a product was produced by whom". We can verify the history, location and application of a product through the lot number recorded on the documents.

DIFFERENCE BETWEEN TRACEABILITY & IDENTIFICATION :-

| |||||||||||||||||||||

HOW TRACEABILITY CAN BE IMPLEMENT IN ANY ORGANISATION? | . |

Material lot or Batch code traceability rule:-

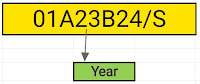

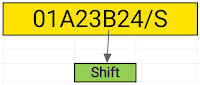

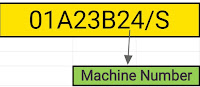

- First write the date of the day on which the part was manufactured or received. For example, if manufactured on the first date, then write 01.

- Write the code according to the month code like 'A' for January and 'B' for February. Like this, 'C' is written for March and 'D' is written for April.

- After that write the year and definitely mention the shift so that tracing can be easy.

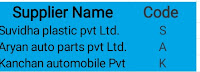

- Mention the machine number on which the part is manufactured and if parts are received by a supplier, we can trace each supplier through an assigned number or code.

Hope! you will understand the topic of Traceability.

Thanks for visiting 👍

Some of related question that help to improve your basic knowledge.

- Engineering Drawing | Angle of Projection.

- What is JIT (Just In Time) manufacturing?

- To know about Defect analysis

- What do you mean by Quality control?

- What is Quality assurance? Available in Hindi also.

- Meanings of Quality?

- Origin points of quality circle in Japan

- TQM

- What is quality assurance?

- What is quality control?