12 STEPS OF QUALITY CIRCLE

Hello friends, Today we are discussing about 12 steps of Quality circle.

These 12 QC steps are most important role play in finding problem root cause and solution implementation with help of some QC tools. If we are not going right path to resolve problem, then how to finding correct root cause of the problem? Without 12 QC steps follow sequencing, we are not resolve the problem, and problem comes back. So these 12 QC steps are using as sequential and work step by step will successful. If we are not reach at target then again repeat the process of QC steps.

There are 12 steps of Quality circle are as follows:

- Identification of work related problems

- Selection of problem

- Define the problem

- Analyze the problem

- Identification of cause

- Finding out the root cause

- Data analysis

- Developing solution

- Foreseeing probable resistance

- Trial implementation

- Regular implementation

- Follow up & review

STEP-1 Identification of work related problem:

In this step, we identify the problem that arises in our organization. These problems are write down and generate a list of problems using "Brainstorming". These priorities problems are divided into 3 categories, are as follows:

- 'A' Category Problem

- 'B' Category Problem

- 'C' Category Problem

'A' Category Problem:

'A' Category Problem is that problem in which minimum involvement of other departments in solving them.

'B' Category Problem:

'B' Category Problem is that problem in which involvement of other departments is necessary.

'C' Category Problem:

'C' Category Problem is that problem in which management sanction may be needed for implementing the solution.

STEP-2 Selection of problem

In this step, after categorize the problem, first from 'A' Category list, we are selecting the problem based on past data or system using 'Pareto analysis' or 'Rating' and register this.

STEP-3 Define the problem

In this step, Problem is proper define with the help of Brainstorming. Make a flow chart of entire process of work areas and highlight that area where problem may be occurred.

STEP-4 Analyse the problem

In this step, analysis calls for data collection on all possible aspects of the problem.

For example:

- Number of times the problem occurred.

- Defect quantity

- Effect of the problem in detail.

Data collection activity is very important role in analysis of the problem. After that priorities the problem using Pareto chart.

Pareto chart:

In 7 QC tools Pareto chart is very important role in defect analysis. Pareto diagram helps us to do priorities after analyzing the problem.

It is a prioritisation tool.

STEP-5 Identification of causes

In this step, using brainstorming and make the cause & effect diagram to find out the significant cause of the problem into all probable causes. Circle have an idea of causes of problem. Remember that problem may have multiple causes. Circle team must find out the probable causes and list them and also try to arrive the significant cause.

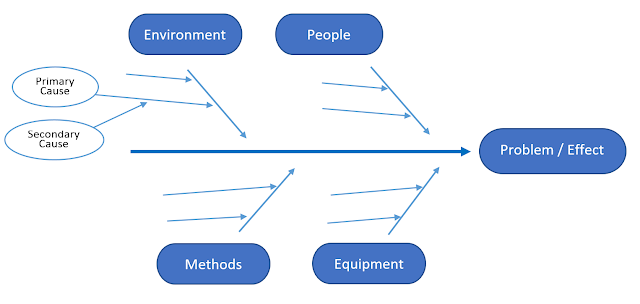

Cause & Effect Diagram:

Cause & effect diagram is very important tool in quality circle. It is also known as Ishikava diagram.

Fishbone diagram is a tool to identify potential cause, root cause to identified after validation.

STEP-6 Finding out the root cause

In this step, with the help of why why analysis technique, we find out the actual root cause of the problem, and take countermeasure on it. Root cause analysis is very important role in Quality Circle. After finding root cause of problems, then we are going to next step. Without finding root cause, we are not take actual path to solution implementation. So in this step brainstorming is also necessary.

STEP-7 Data analysis

Analysis may call for further floor exercise, work spot, follow up and study. In this step, circle may use histogram, stratification, scatter diagram etc. which would help easy comprehension and make comparison possible.

STEP-8 Developing solution

After finding the actual root causes, Quality circle team develop a appropriate solution in this step. In this step, using countermeasure matrix or action plan techniques which shows time bound and responsibility shared activity.

STEP-9 Foreseeing probable resistance

With the help of brainstorming, identify the potential problem and find countermeasure to overcome them.

STEP-10 Trial implementation & check performance

In this step, like step no. 8, on that basis we do a trial and check performance to know that our desired result have been achieved or not.

STEP-11 Regular implementation

Once validity of solution is checked and improvement observed with data, regular implementation can be effected.

STEP-12 Follow up & review

Incorporate the changes in relevant documents for Standardization & in the working system such as process flow sheet, quality control plan, work instructions, inspection standards etc. Monitor preferably for next six month regularly.

Hope, you will understand this topic.

Thanks

Some questions that you should read:-

No comments:

Post a Comment