POKA-YOKE

- Introduction

- Categories of Poka Yoke Devices

- Traditional Methods for Error Prevention

- Enhanced Approaches for Error Prevention

- Historical Background

Introduction:

Poka-yoke devices are strategically implemented within companies to minimise errors, particularly in high-risk areas. These devices serve to make processes foolproof, effectively preventing mistakes and ensuring smooth, safe operations.

Definition:

Poka-Yoke, also known as mistake-proofing, serves as a safeguard against errors. It's a system designed to prevent mistakes from occurring, but if they do happen, it promptly detects and allows for correction.

Mistake-proofing, or Poka-Yoke, encompasses activities aimed at raising awareness, detection, and prevention of mistakes that could negatively impact:

- Our customers and consumers, resulting in defects

- Our employees, potentially leading to injuries

The ultimate goal is to achieve zero defects and injuries, ensuring the highest standards of quality and safety.

Categories of Poka Yoke Devices:-

1. Awareness:

Awareness ensures that everyone from process owners to shop floor associates are aware of potential mistakes. These devices alert the operator about the potential for errors or guide them through the correct process to prevent mistakes. This entails designing processes and products in a manner that facilitates easy detection and prevention of defects.2. Detection:

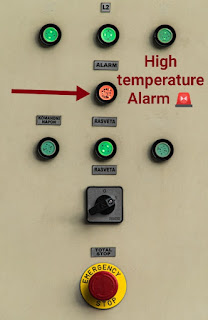

Detection involves acknowledging the possibility of mistakes occurring and installing systems to identify them swiftly, halting them before they impact the customer. These devices identify when an error has occurred, allowing for immediate intervention or correction. While detection Poka yoke devices don't prevent errors outright, they provide timely signals or alarms to alert users, enabling prompt corrective action. For instance, a high-temperature alarm serves as an effective detection mechanism.3. Prevention:

Prevention means that we will such changes in design so that any mistake cannot be done by mistakenly. Not allowing the chances for the error to occur within the first place.Prevention is the best other than. Prevention devices are designed in such a way that mistakes are made impossible.

Traditional Methods for Error Prevention:

- Reprimand workers

- Give motivational talks to worker (Tell them to pay attention and be more careful)

- Retrain workers

Enhanced Approaches for Error Prevention:

- Improve the process

- Make wrong action more difficult

- Make it easier to discover the error that does occur.

Historical Background:

Poka yoke invented by Shigeo Shingo.Shigeo shingo (1909-1990) was a Japanese industrial engineer who was considered as the world's leading expert on manufacturing practices and the Toyota Production System. In 1945, at the end of second World war, he started to works at the Japan Management association (JMA) in Tokyo and becoming a consultant focused on the improvement of factory management.

Poka yoke means to mistake proof the process.

First Poka yoke device:

He suggested that :-

A small plate is placed in front of the parts box, and the worker's first task is to take two springs out of the box and place them on the plate.

Then the worker assemble the switch, if any spring remains on the plate, then the worker knows that he has forgotten to insert it.

Then new procedure completely eliminated the problem of the missing spring.

Thank you.

Some of related question that help to enhance your basic knowledge.

No comments:

Post a Comment

If you have any doubt, please let me know