POISON TEST FOR INSPECTOR

Hello guys, today we will discuss on Poison test. Hope, you'll understand this topic.

First, thanks for visiting.

Today we will talk about below topics which are related to Poison test:

- Introduction

- Why Poison test is necessary?

- How Poison test is done in an organization?

INTRODUCTION:

It is the cross verification method of inspector's competency which shows that inspector are able to identify all defective parts. Shift supervisor is most responsible to done this activity. It is a periodic test for Inspector that are most important to check their defect capture ability. Mostly, It is used for final Inspectors and PDI inspectors. On the other hand, it can be used for Incoming inspection, Inprocess inspection and any other inspection stages.

HOW POISON TEST IS DONE IN AN ORGANIZATION?

There are several steps for implementing poison test for Inspector:-

- Firstly, 02 defective parts are mixed with 48 ok parts in 50 parts lot and offered to inspector for inspection.

- These defective part quantities can be 2%, 3% or 5% of any lot. It is done in attribute and visual inspection.

- Note that any identification marks have been put on them to identify the NG parts.

- When this lot offer to Inspector for inspection, he should be unaware about this poison test.

- Now, let's see that what he can capture the NG parts.

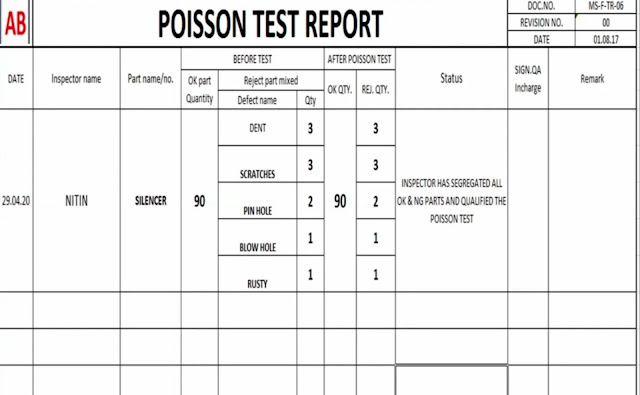

- If he segregated and captured all defective parts. Then it will be record in poison test report.

- And if he can't identify the NG parts, then identify cause of their inadequate inspection and give retraining to him.

- Again poison test will be done on next day of that inspector.

- Do poison test for all visual Inspectors every month. For new inspectors, before deputing him on first line visual inspection of RI (Receiving inspection), IP (Inprocess inspection), PDI (Pre-dispatch inspection).

- Frequency of poison test is depend on complexity, customer requirements, and problem occurred into process. For suggestion, it should be done per month for every inspector.

- Poison test plan make before doing this process.

WHY POISON TEST IS NECESSARY?

There are some points that shows necessity of poison test:-

- Poison test is mandatory to check inspector's defect capture ability.

- To avoid defect outflow from your end to customer end.

- It shows the new inspectors who are deputing on first line, are qualified or not.

We hope you will understand this topic.

Thank you.

Some important question that you should read to improve skill:-

No comments:

Post a Comment