Process capability Studies:-

Process capability compares the output of a control process to the specification limit. Whereas in SPC we compare the output with the control limit whether the process is stable or not.

Capable Process is that process where all measurements are within the specification range. The main purpose of a capability study is to determine whether any process is capable of meeting certain requirements or not. The efficiency of a process can be assessed through the determination of the probability distribution, its size, center, and spread. In theory, a capability study should be conducted for each product dimension and each quality attribute. In practice, however, those familiar with a process are usually able to identify certain characteristics that deserve a full capability study, typically those features that experience has shown difficult to understand for specification. For example, suppose a customer requires a certain process output from 30 to 40, such as:

- The arrival time of the delivery vehicle should be between 30 to 40 minutes after hours.

- Manufactured pumps must have an output between 30 psi to 40 psi.

- Plating thickness should be from 30 to 40 mm.

In these examples, the requirement 30 to 40 is called the specification, which typically covers the endpoints.

Before understanding CP we have to understand this diagram.

In bilateral tolerance, LSL & USL are the specification limit which is given by customer. It is also called as voice of the customer.

A curve shape lies between LSL and USL. It shows our process behavior. This make accordance with actual product output data.

USL: It means Upper specification limit of the tolerance.

LSL: It means Lower specification limit of the tolerance.

For example: If any part specification is 6±0.5, i.e. USL is 6.5 and LSL is 5.5

Cp is always greater than or equal to Cpk.

Cp defined as:

USL-LSL represents the width of the spec.

6σ represents the width of the process or standard deviation.

Cpk:

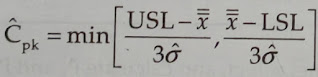

Cpk is a process capability index that assesses how many the process is close to mean and center within the tolerance limit. It is also known as the centering index. Cpk is never greater than Cp. Efficiency measurement Cpk penalizes a process which means out-of-centre. Cpk takes into account process centralization and is given by as shown in pic,